How Laser Cutting Machines are Revolutionizing the Jewelry Industry

The jewelry industry requires a creative flair to produce beautiful designs. These days laser cutting technology is transforming jewelry-making techniques by offering precision and speed. This is helping designers and jewelry makers to produce intricate designs and patterns.

Such technological innovations are revolutionizing the jewelry industry by making it easier to create any design. Let’s explore how a laser cutting machine is helping consumers and designers alike.

The Evolution of Jewelry-Making: Traditional Methods vs. Laser Cutting

Traditionally jewelry making was a very time consuming and demanding task. Hand-carving included shaping the materials of metal, wood, and stone to create wearable shapes. This was done using a knife or a small hammer. In this the designer creates jewellery by putting the metal into mold. The metal must be melted before being poured into these molds.

Engraving is an old technique in which the design is etched onto the surface of the metal. It requires special tools like chisel, or gravers to carve visible details. Unlike all these traditional methods laser cutting jewellery is a much easier modern alternative. A laser cutting machine offers greater accuracy and can help in creating jewellery with better efficiency and creativity

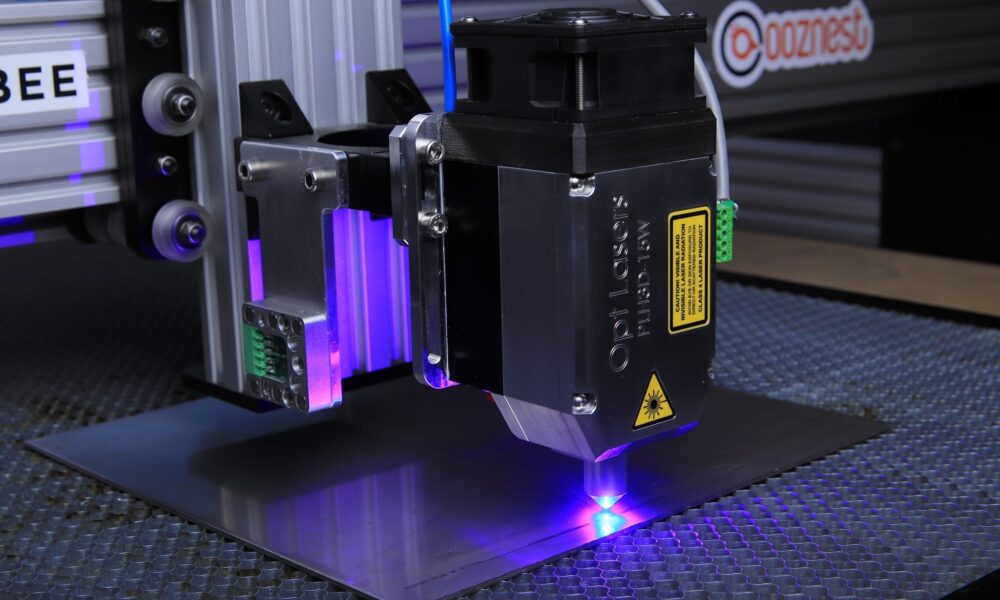

How Laser Cutting Works in Jewelry Design

It is very easy to create visually appealing designs of jewelry using this machine. A design software like CAD is used to prepare jewelry designs which is then set up in the machine. You can set up the machine according to the material and design thickness. The computer-controlled system helps in monitoring the machine and directs a laser beam. This can create a smooth finish without any additional manual work. It works effectively on various materials including metal, wood, plastic, canvas, and more.

Materials Used in Laser-Cut Jewelry

The laser cutting in the jewellery industry is commonly used on the following materials:

- Metals (e.g., gold, silver, platinum): Precious metals like gold, silver and platinum require careful cutting for precise designs. Laser machines can offer detailed engraving on these metals providing beautiful jewelry.

- Acrylics and Plastics: Laser-cut acrylic jewelry is famous for its affordability and vibrant range of colors. These offer versatility in designs and provide good durability.

- Wood and Leather: For those who love eco-friendly jewlery laser cutting offers creative freedom to work with natural materials. It can create intricate and unique patterns on natural materials.

- Gemstones and Inlays: Unlike traditional designing process, laser cutting allows a custom setting for inlaying precious gemstones. This helps in enhancing the design possibilities.

Advantages of Laser Cutting in Jewelry-Making

A fiber laser cutter brings various benefits to the jewelry industry:

Precision and Intricacy: Designs that need precise detailing are difficult to create by hand. Designers can use laser cutting to achieve such designs.

Customization and Personalization: This technology allows designers to fulfil various designing demands of jewelry customers. It is because this machine can create various designs with high-quality detailing.

Efficiency and Reduced Waste: Using laser cutting machines can offer high speed and reduce production cost. It also helps in minimizing waste and is highly efficient in reducing material wastage.

Versatility in Styles: Due to its versatility the laser cutting in the jewellery industry is famous for creating various types of designs. This can help in creating classic, modern , minimalistic and ornate designs.

Applications of Laser Cutting in the Jewelry Industry

By using the carbon laser cutter anyone can create or enhance various types of jewelry.

Engraving: These machines can be used for engraving personalized rings, bracelets, broches, and necklaces. Whether it is an initial or some special symbol, it can be done using these machines.

Custom Cut-outs and Patterns: You can easily create unique pendants, earrings, and eye-catching charms with intricate shapes and patterns with these machines.

Setting and Shaping: These cutting machines can help in setting and shaping precious gemstones and pieces with fine detailing.

Bridal and Custom Collections: Due to the fast speed these machines can help jewelers for custom engagement rings, wedding bands, and other items.

Future Trends in Laser-Cut Jewelry

In future laser-cut jewlery can increase in demand due to high customization, and eco-friendly benefits. Some new AI assistance may lead to new materials to effectively work with these machines. The integration of such AI technology can help in advancing the laser technology making it more finer and appealing. This can lead to its expansion in a broader market.

Conclusion

It is evident that laser cutting machines are transforming the jewelry industry. It can provide designers with new flexibility, precision and creative freedom. You can explore fine jewelry which is laser-cut for your next purchase and express your styling choices.

Source: How Laser Cutting Machines are Revolutionizing the Jewelry Industry